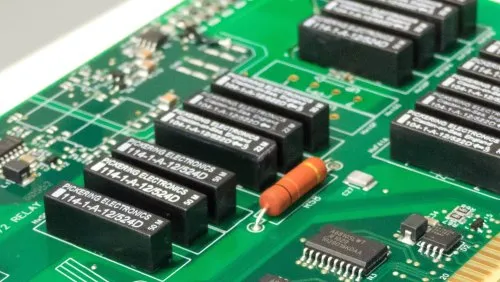

Turnkey vs Consigned PCB Assembly Which is Right for You

When it comes to manufacturing printed circuit boards (PCBs), choosing the right assembly model can significantly influence your project’s cost, quality, and delivery time. Among the most common options are turnkey PCB assembly and consigned PCB assembly. Each method has its unique strengths and limitations—and understanding those differences is essential for making an informed decision.

Whether you’re a hardware startup developing your first prototype or a seasoned manufacturer planning for mass production, this article will help you compare turnkey and consigned PCB assembly, highlighting their pros, cons, and which one is better suited for your project.

What Is Turnkey PCB Assembly?

Turnkey PCB assembly is a full-service solution in which the assembly provider manages the entire process—from component sourcing and PCB fabrication to final assembly and testing. You only need to provide the necessary design files (like Gerber, BOM, and assembly drawings), and the provider handles the rest.

Key Features:

-

Provider sources components

-

PCB manufacturing is handled in-house or through partners

-

Complete assembly and testing are included

-

Single point of contact and responsibility

What Is Consigned PCB Assembly?

In a consigned PCB assembly model, you (the customer) supply all or most of the materials—such as the PCB boards, components, and even stencils—and the assembler focuses solely on putting everything together according to your design.

Key Features:

-

Customer procures and supplies components and bare boards

-

Assembler is responsible only for the actual assembly process

-

You maintain control over the supply chain

-

Suitable for special or proprietary components

Comparing the Two: Turnkey vs. Consigned

Now, let’s break down the major differences between turnkey and consigned assembly across key areas like cost, speed, quality, and flexibility.

1. Supply Chain Management

-

Turnkey: All components and PCBs are sourced by the assembly provider, often through trusted suppliers or in-house systems. This reduces the burden on your team.

-

Consigned: You’re responsible for sourcing and managing all parts. This can be time-consuming and error-prone, especially if you’re dealing with multiple suppliers.

✅ Winner: Turnkey – Ideal for teams that want a hands-off, streamlined experience.

2. Project Timeline and Speed

-

Turnkey: Providers often have bulk relationships with suppliers and can expedite component procurement and manufacturing. Turnkey projects usually have shorter lead times.

-

Consigned: Delays in shipping components to the assembler or sourcing rare parts can significantly slow down the timeline.

✅ Winner: Turnkey – Best for fast prototyping and rapid market entry.

3. Cost Considerations

-

Turnkey: While the upfront quote may seem higher, it often includes discounted bulk component rates, reduced shipping costs, and less overhead.

-

Consigned: You may save money by sourcing low-cost components yourself—especially if you have preferred vendors or access to surplus inventory.

✅ Winner: Depends – Turnkey offers predictable pricing and less risk, but consigned can be cheaper for companies with established supply chains.

4. Quality Control

-

Turnkey: The provider is fully responsible for quality at every stage, from sourcing components to final inspection. This allows for consistent quality assurance processes.

-

Consigned: The assembler only verifies the materials they receive, meaning if any component is faulty, the responsibility lies with you.

✅ Winner: Turnkey – Lower risk of counterfeit or defective parts and end-to-end accountability.

5. Risk Management

-

Turnkey: The provider assumes responsibility for shortages, substitutions, and replacements. They often have backup options and supplier alternatives.

-

Consigned: You’re responsible for ensuring every component is correct, complete, and on time. If a part is missing or incompatible, it’s your problem to solve.

✅ Winner: Turnkey – Safer and more reliable, especially for complex builds.

6. Design Flexibility and Custom Components

-

Turnkey: Most providers support standard and widely available components. Specialty or rare parts may take longer to source—or you might need to provide them yourself.

-

Consigned: You can supply proprietary components or special inventory from your own stock.

✅ Winner: Consigned – Better for niche applications or custom builds.

7. Scalability

-

Turnkey: Perfect for scaling up production quickly—whether you’re moving from prototype to full production or increasing order volumes.

-

Consigned: Can be difficult to scale due to the logistical burden of sourcing and managing increasing quantities of parts.

✅ Winner: Turnkey – A better long-term solution for growing businesses.

8. Who Owns the Process?

-

Turnkey: The provider has full control, and you have less visibility into each step unless transparency is explicitly offered.

-

Consigned: You maintain control over every part of the process—ideal for teams with specific preferences and internal engineering oversight.

✅ Winner: Depends – Turnkey is hands-off; consigned gives you full control.

When Should You Choose Turnkey PCB Assembly?

You should go with turnkey assembly if:

-

You’re on a tight deadline

-

You don’t have in-house procurement expertise

-

You want a single vendor to handle everything

-

You’re scaling production and need reliability

-

You’re launching a new product and need rapid prototyping

Turnkey is also ideal for companies that prioritize speed, efficiency, and low risk.

When Is Consigned PCB Assembly a Better Fit?

Choose consigned assembly if:

-

You already have components on hand or proprietary parts

-

You want full control over sourcing and inventory

-

You’re working with specialty materials

-

You have a trusted internal team or supply chain

Consigned assembly works well for R&D labs, custom electronics, or companies with established procurement channels.

Hybrid Approach: A Middle Ground

Some manufacturers offer partial or hybrid models, where you supply certain critical or custom components, and they handle the rest. This approach gives you flexibility and control without fully committing to either method.

It’s a great choice when:

-

You need to use legacy or hard-to-find parts

-

You have some internal inventory but want help sourcing others

-

You’re transitioning from prototyping to production

Final Thoughts

Choosing between turnkey and consigned PCB assembly isn’t a one-size-fits-all decision. It depends on your goals, team capabilities, timeline, and budget.

-

If you value speed, simplicity, and peace of mind, turnkey is the way to go.

-

If you need customization and total control, consigned might suit you better.

-

And if you want the best of both worlds, explore hybrid options.

Whichever path you choose, the key is finding a reliable PCB assembly partner who understands your needs and can deliver consistent, high-quality results.