Geogrids are pivotal in modern infrastructure projects, offering essential reinforcement and stability for various soil and construction applications. As the demand for robust and efficient infrastructure solutions grows, geogrid factories are pushing the envelope with innovative technologies and practices. This blog explores how Geogrid factory are advancing the field of infrastructure, highlighting the latest innovations, trends, and their impacts on construction projects.

Understanding Geogrids and Their Significance

What Are Geogrids?

Geogrids are synthetic materials designed to enhance soil stability and load distribution. Made from high-strength polymers such as polypropylene or polyester, they feature a grid-like structure that interlocks with surrounding materials to improve performance.

Importance of Geogrids in Construction

- Soil Reinforcement: Geogrids strengthen soil, making them crucial for embankments, retaining walls, and roadways.

- Load Distribution: They effectively distribute loads across a larger area, preventing soil deformation and enhancing stability.

- Erosion Control: Geogrids help control soil erosion and support vegetation, particularly in erosion-prone areas.

Innovations Shaping Modern Geogrid Factories

1. Cutting-Edge Manufacturing Technologies

Geogrid factories are adopting advanced manufacturing technologies to produce high-performance materials:

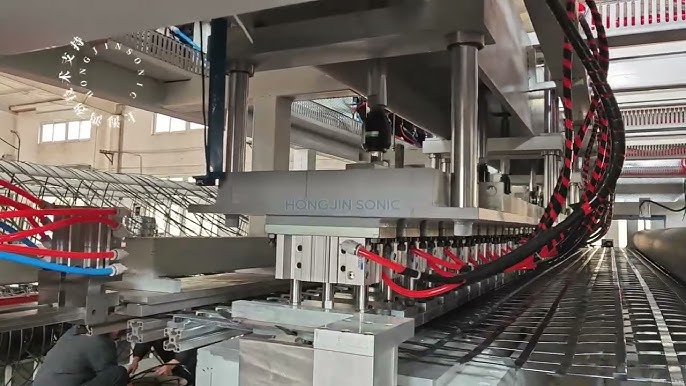

Advanced Extrusion Processes

- Precision Extrusion: Modern extrusion machines ensure consistent thickness and quality of geogrid sheets.

- High-Temperature Processing: Enhanced polymer processing techniques improve the mechanical properties of geogrids.

Sophisticated Stretching Techniques

- Uniaxial and Biaxial Stretching: New stretching technologies align polymer chains to increase tensile strength and performance.

- Controlled Orientation: Precision control of the stretching process ensures uniform material properties.

Innovative Punching and Forming

- High-Accuracy Punching: Advanced punching tools create precise grid patterns, ensuring consistent performance.

- Automated Forming: Modern forming machines streamline production, improving efficiency and product quality.

2. Enhanced Quality Control and Testing

Quality control is critical in geogrid production. Modern factories implement rigorous testing procedures to ensure performance and reliability:

Material Testing

- Tensile Strength Evaluation: Testing the geogrid’s ability to withstand pulling forces without failure.

- Durability Assessment: Evaluating resistance to environmental factors such as UV radiation, chemicals, and temperature variations.

Performance Testing

- Reinforcement Effectiveness: Measuring how well geogrids reinforce soil and prevent deformation.

- Load Distribution: Assessing how geogrids distribute loads across reinforced areas.

Compliance with Standards

- ASTM Standards: Ensuring geogrids meet industry performance and safety guidelines.

- ISO Certifications: Adhering to quality management and environmental practices.

3. Sustainable Manufacturing Practices

Sustainability is a growing focus in geogrid manufacturing. Factories are adopting eco-friendly practices to reduce their environmental impact:

Energy-Efficient Technologies

- Energy-Conserving Machinery: Using energy-efficient equipment to minimize energy consumption and emissions.

- Renewable Energy Sources: Incorporating renewable energy to further reduce the carbon footprint.

Recycling and Waste Management

- Recycled Materials: Utilizing recycled polymers to support sustainability and reduce waste.

- Waste Reduction Practices: Efficient waste management processes to minimize production waste.

Eco-Friendly Materials

- Biodegradable Options: Developing biodegradable geogrid materials to minimize environmental impact.

4. Customization and Advanced Solutions

Modern geogrid factories offer a range of customization options to meet specific project needs:

Custom Grid Designs

- Tailored Patterns: Designing geogrids with specific grid patterns to address unique project requirements.

- Flexible Production: Advanced manufacturing techniques allow for customized designs and specifications.

Specialized Coatings

- Enhanced Durability: Applying coatings to improve resistance to UV radiation, chemicals, and environmental factors.

- Functional Enhancements: Coatings can also enhance performance for specific applications.

Innovative Applications

- New Material Technologies: Research and development lead to innovative geogrid materials with improved properties.

- Emerging Solutions: Developing geogrids for new challenges in infrastructure and environmental management.

The Impact of Geogrid Innovations on Infrastructure Projects

1. Improved Performance and Reliability

Innovative geogrid technologies contribute to:

Enhanced Load-Bearing Capacity

- Effective Reinforcement: High-strength geogrids provide superior reinforcement and load distribution, reducing the risk of soil failure.

Long-Term Durability

- Extended Lifespan: Durable geogrids enhance the longevity of infrastructure projects, reducing the need for frequent repairs.

2. Cost-Effectiveness and Efficiency

Geogrid innovations lead to cost savings and improved efficiency:

Reduced Construction Costs

- Lower Overall Costs: High-performance geogrids decrease the need for additional reinforcement, reducing construction expenses.

Faster Project Completion

- Efficient Production: Streamlined manufacturing processes and high-quality materials enable quicker project completion.

3. Environmental Benefits

Sustainable geogrid production practices support environmental goals:

Reduced Environmental Impact

- Eco-Friendly Manufacturing: Energy-efficient technologies and recycled materials minimize the environmental footprint of production.

Sustainable Construction Practices

- Greener Projects: Durable and eco-friendly geogrids contribute to sustainable construction practices and long-term environmental health.

Case Studies: Geogrid Innovations in Action

1. Urban Infrastructure

Modern geogrids have enhanced urban infrastructure projects, including roadways, retaining walls, and green spaces. Innovations address challenges such as high traffic loads and limited space.

2. Environmental Restoration

Geogrids have played a crucial role in environmental restoration projects, such as erosion control and land reclamation. Advanced materials and manufacturing techniques have supported successful outcomes.

3. Large-Scale Construction

In major projects like highways and bridges, innovative geogrids provide essential reinforcement and stability. High-strength geogrids support complex engineering solutions and ensure structural integrity.

Conclusion

Geogrid factories are leading the way in advancing infrastructure through innovative technologies, sustainable practices, and customized solutions. By enhancing performance, efficiency, and environmental responsibility, these factories are shaping the future of construction and civil engineering. As infrastructure needs continue to evolve, geogrid factories will remain pivotal in driving progress and ensuring the success of critical infrastructure projects worldwide.