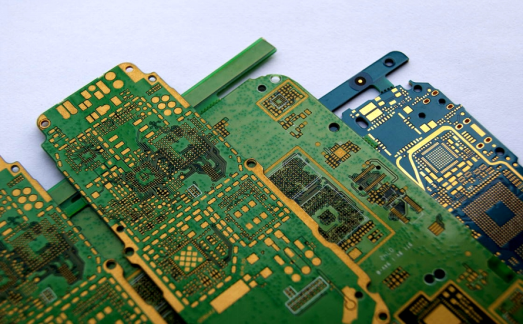

With China dominating the global printed circuit board (PCB) manufacturing industry, selecting the right PCB manufacturer in the country is essential for businesses looking to develop high-quality electronics products. However, with so many manufacturers available, making the right choice can be challenging. In this article, we’ll explore the key factors to consider when choosing the best PCB manufacturer in China to ensure your project’s success.

1. Quality Standards and Certifications

When evaluating a PCB manufacturer in China, the first consideration should be their adherence to international quality standards. PCBs are crucial components of electronic devices, and any defect or quality issue can lead to significant performance problems.

Look for manufacturers that hold certifications like:

- ISO 9001(Quality Management Systems)

- IPC-A-600(Standards for PCB acceptability)

- UL Certification(Safety standards for electronic components)

- RoHS Compliance(Restriction of hazardous substances)

These certifications indicate that the manufacturer adheres to strict quality standards, ensuring your PCBs will meet performance and safety requirements. Additionally, ask if they conduct rigorous testing, including electrical testing, functionality checks, and inspection protocols, to catch defects before shipping.

2. Manufacturing Capabilities and Technology

The complexity of your project will determine the type of PCBs you need, such as single-layer, multi-layer, flexible, or rigid-flex boards. It’s essential to choose a manufacturer that has the appropriate technological capabilities to meet your specific needs.

Key factors to assess include:

- Types of PCBs produced: Ensure they can handle the specific type of PCB your project requires.

- Advanced manufacturing techniques: For projects that require high-density interconnect (HDI) PCBs, high-frequency boards, or flexible circuits, confirm the manufacturer has experience with these advanced technologies.

- Equipment and facilities: A modern, well-equipped manufacturing facility can handle complex designs with precision and high quality.

A PCB manufacturer with cutting-edge equipment and expertise in complex designs will ensure your boards are manufactured to precise specifications, especially for high-frequency or multi-layer PCBs.

3. Experience and Industry Expertise

Experience matters when selecting a PCB manufacturer. A company with years of experience in the industry is more likely to understand the complexities of different projects, offer valuable insights, and handle unexpected challenges.

Look for manufacturers that have a proven track record in industries similar to yours. Whether you need PCBs for telecommunications, medical devices, automotive, or consumer electronics, working with a manufacturer that has experience in your field ensures they are familiar with industry-specific requirements and standards.

4. Lead Times and Production Capacity

Meeting production deadlines is critical, especially in industries with tight timelines. When choosing a PCB manufacturer, inquire about their lead times for both prototyping and mass production. A manufacturer with a fast and reliable turnaround time can help you bring your product to market faster, giving you a competitive edge.

Additionally, consider the manufacturer’s production capacity. Can they handle both small and large orders? If your business is planning to scale up, you’ll need a manufacturer capable of ramping up production without compromising quality or delaying timelines.

5. Cost Efficiency and Value for Money

Cost is a significant factor when choosing a PCB manufacturer in China, but it’s important to strike a balance between affordability and quality. The cheapest option may not always be the best, as poor-quality PCBs can lead to costly rework or product failures in the long run.

Evaluate pricing in the context of the value offered, considering factors like:

- Materials used: Are high-quality materials being used in the production of your PCBs?

- Design and engineering support: Does the manufacturer offer value-added services such as design review or engineering advice that can improve the performance and cost-effectiveness of your PCBs?

- Testing and quality control: Manufacturers that invest in quality control and testing processes are likely to provide better long-term value, even if their prices are slightly higher.

The goal is to find a manufacturer that offers a fair price without compromising on quality or service.

6. Customer Service and Communication

Effective communication is vital when working with an overseas manufacturer. Time zone differences and language barriers can sometimes complicate the production process, so choose a manufacturer that prioritizes clear, transparent communication and offers strong customer support.

Key considerations include:

- Responsiveness: How quickly does the manufacturer respond to inquiries or issues?

- Language proficiency: Ensure the manufacturer has representatives who can communicate fluently in your preferred language to avoid misunderstandings.

- Project management support: A dedicated account manager or project coordinator can ensure that your project stays on track and any issues are resolved quickly.

Good customer service is essential for building a long-term partnership with your manufacturer, ensuring that your requirements are clearly understood and met throughout the production process.

7. Design and Engineering Support

Many Chinese PCB manufacturers offer additional design and engineering services that can help optimize your PCB design for manufacturability (DFM). This can be especially valuable during the prototyping phase, where minor adjustments to the design can significantly reduce costs or improve performance.

If you’re not an expert in PCB design, partnering with a manufacturer that provides these services can help you avoid costly mistakes, streamline production, and improve the overall functionality of your PCB.

8. Prototyping and Testing Services

Before moving to mass production, it’s crucial to test your PCB design through prototyping. Ensure the manufacturer offers prototyping services with quick turnaround times so you can validate your design before committing to full-scale production.

Additionally, inquire about the manufacturer’s testing capabilities. High-quality PCB manufacturers will have robust testing processes in place, including:

- Functional testing

- Electrical testing

- Thermal analysis

- Environmental stress testing

These tests ensure that the PCB can withstand real-world conditions and meet the performance requirements of your application.

9. Sustainability Practices

As environmental responsibility becomes increasingly important for businesses, choosing a manufacturer that follows sustainable practices is a growing priority. Look for manufacturers that comply with environmental standards like RoHS (Restriction of Hazardous Substances) and implement eco-friendly practices in their manufacturing processes.

This not only ensures compliance with international regulations but also aligns your company with responsible and sustainable business practices.

Conclusion

Choosing the best PCB manufacturer in China requires careful evaluation of factors such as quality standards, technological capabilities, cost efficiency, and customer service. By thoroughly assessing these key aspects, you can select a partner that not only meets your technical requirements but also offers reliability, scalability, and value for money.

The right PCB manufacturer will not only help bring your designs to life but will also be a valuable partner in ensuring the success of your electronics projects for years to come.