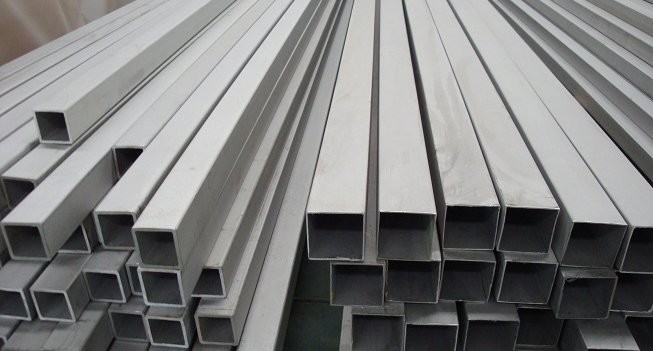

Square seamless tubes have become essential in various industries, serving as structural supports, frames, and conduits. While their production involves intricate processes, tube fabricators have mastered the art of creating square tubes with precision and quality. You are at the right place if you want to explore the fascinating world of seamless square tube production. We will shed light on the techniques, materials, and machinery pipe suppliers use in the manufacturing process.

What are seamless pipes?

Seamless pipes are cylindrical tubes made from solid steel billets, manufactured without any welding seams or joints. This method ensures uniformity in composition and strength, making them ideal for critical applications in industries such as oil and gas, petrochemicals, and construction. The absence of seams enhances their durability and ability to withstand high pressure and temperature conditions.

Understanding seamless tube manufacturing:

Before delving into the specifics of square tube production, it’s crucial to comprehend the general process of seamless tube production. Pipe operators produce seamless pipes and tubes from solid billets or cylindrical steel bars. The first step involves heating the billet, often induction heating until it becomes malleable.

Subsequently, seamless tube manufacturers pierce the solid billet with the help of a piercing mill. It creates a hollow shell, which pipe producers elongate and shape through a series of rolling mills. These mills reduce the diameter of the pipes while increasing their length.

Finally, they cut the tubes to the desired lengths. The tubes undergo various finishing processes, such as straightening, heat treatment, and inspection.

Material selection and preparation:

Manufacturers typically produce seamless square tubes using carbon steel, stainless steel, or other alloy steels. The material selection depends on the intended application and the desired properties of the finished product. High-quality raw materials undergo rigorous testing for chemical composition, mechanical properties, and microstructure.

The testing process ensures compliance with industry standards. Once line pipe suppliers approve the materials, they cut them into suitable lengths. In addition, they also inspect the pipes and tubes for any surface defects.

The cold drawing process:

The cold drawing process plays a crucial role in achieving the desired shape and dimensions of seamless square tubes. In this process, pipe producers pull the tube through a series of dies that gradually reduce its diameter. However, the dies maintain the square shape of the tube.

Initially, the tube passes through a die with a circular opening, which reduces its diameter and eliminates any surface imperfections. Subsequently, it goes through a series of square-shaped dies that progressively shape the tube into a square cross-section.

Finishing and quality assurance:

Once seamless tube manufacturers produce the square tube, it undergoes several finishing processes to ensure its dimensional accuracy, surface quality, and mechanical properties. These processes include straightening, cutting, and heat treatment. Straightening machines eliminate residual stress and deformations, ensuring the tube’s straightness. Precise cutting machines then trim the square tube to the required lengths.

Heat treatment is critical to enhancing the square tube’s mechanical properties. Pipe suppliers control the heating and cooling processes. Annealing, quenching, and tempering improve its strength, hardness, and flexibility. After heat treatment, manufacturers thoroughly inspect square tubes to meet stringent quality standards. They employ various non-destructive testing methods, including ultrasonic testing and visual inspections. These methods help in the detection of any surface defects or irregularities.

Also Read: How does a plumber unclog a pipe?

In the end:

Producing seamless square tubes is a complex yet fascinating process involving material selection, cold drawing, and meticulous finishing techniques. Seamless pipe and tube producers ensure the highest quality standards and dimensional accuracy through stringent quality control measures.

With their versatility and strength, Square seamless tubes find applications in a wide range of industries. By understanding the intricacies of seamless square tube production, we can appreciate the craftsmanship and dedication involved in creating these essential components.